Probleemstelling:

The rising demand for high power-density and performance of modern powertrains eg in wind turbines, pushes gears towards their limits in terms of power transfer, load capacity, efficiency, durability and reliability. In wind turbine planetary gearboxes, for example, 70% percent of the failures are attributed to the roller bearings, of which 80% is believed to have inadequate lubrication of the rolling contacts as a root cause. Another 26% of failures are designated to failing gear teeth. Also here, inadequate lubrication is the most occurring cause of damage and wear of gear teeth flanks. In order to minimize premature failure and operational and maintenance costs, it is crucial to understand the physics which occur in lubricated bearing and gear contacts, operating under various conditions.

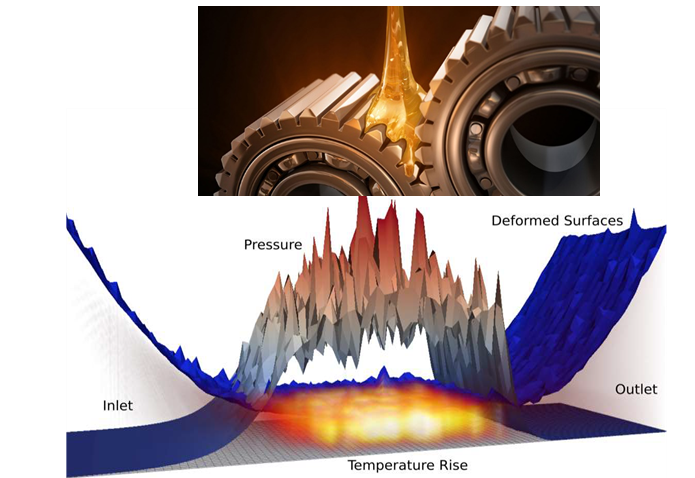

Gears and bearings operate under the so-called thermo-elasto-hydrodynamic lubrication (TEHL) regime. These implies that solid surfaces are just separated by an extremely thin oil film of barely 50nm-1μm thickness. Locally extreme hydrodynamic oil pressures (1-4 GPa) arise, resulting in a local solidification of the lubricant and a significant local elastic deformation of the solid surfaces. At the other hand, the surface roughness, even in the order of nanometers, can strongly affect the lubrication of contacts. Local contact pressure, shear heating, and temperature can be meaningfully changed in presence of surface roughness. Hence, a clear understanding on the behavior of the lubricant in rough contacts can help in proper lubricant selection, and more accurate lifetime estimation for a specific application.

Unfortunately, as it is very difficult to measure contact pressure in lubricated contacts, the precise thermo-mechanical modeling of lubricants in TEHL contacts, remains mostly a blind spot for lubricant suppliers, gearbox and bearing manufacturers, as well as scientists. Hence, there has been an exponential increase of interest in sophisticated and realistic modeling of lubricated contacts using Computational Fluid Dynamic (CFD).

​

​