Probleemstelling:

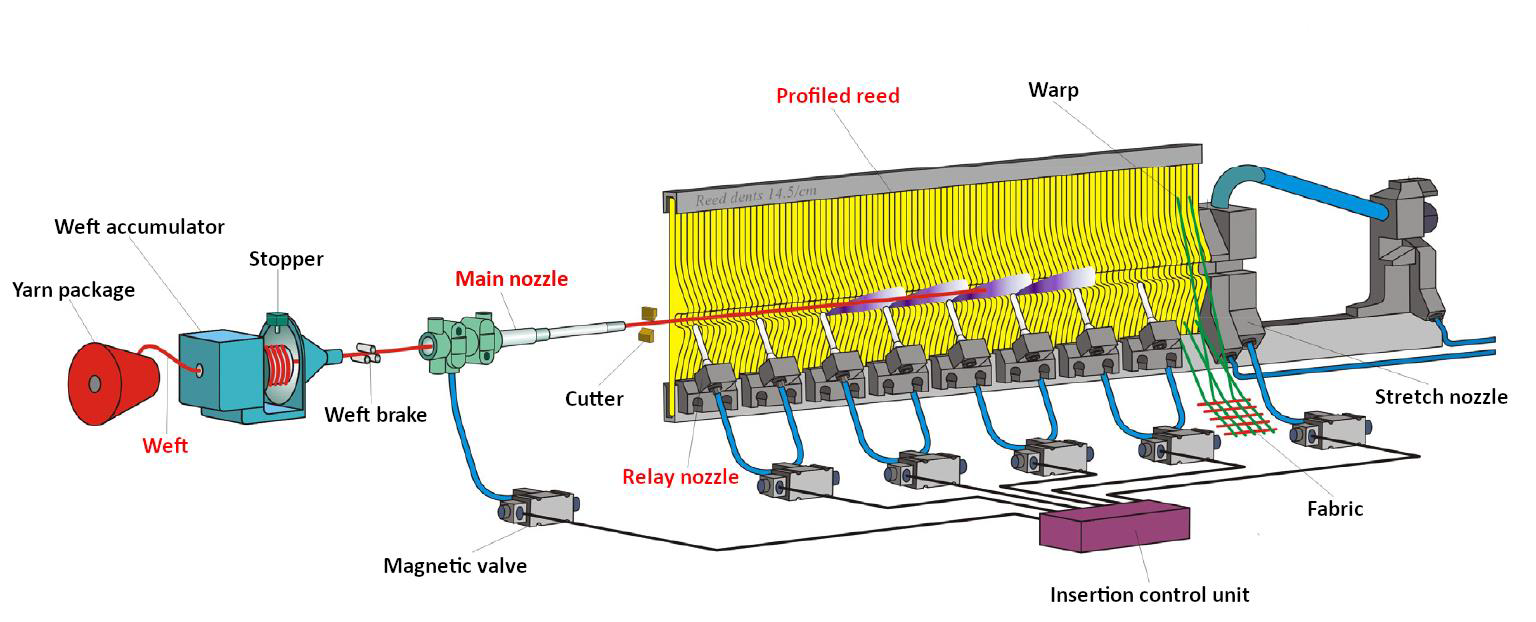

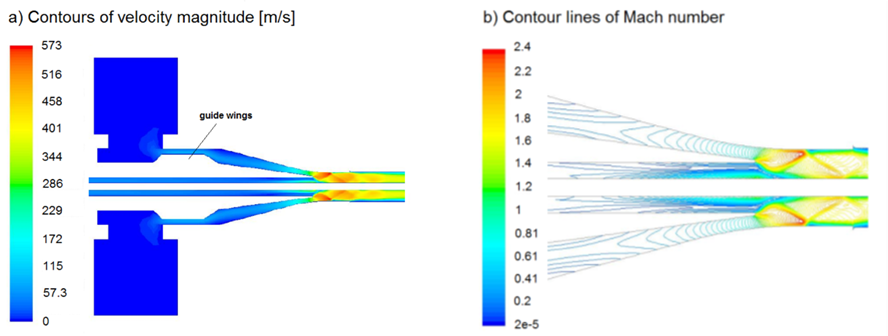

Air jet looms (Figure 1) are very popular weaving machines due to the high insertion rate (up to 2000 insertions per minute) and the reduced number of moving parts compared to projectile and rapier looms. However, the use of compressed air as propelling medium causes a high energy cost (in the order of 10 kWh/kg of woven fabric). Due to the high number of degrees of freedom on a main nozzle, optimizing by means of an experimental campaign is unfeasible, which favours numerical simulations. As high-fidelity models have a high computational cost, researchers often resort to surrogate models. These models require less computational time (order of minutes or even seconds) at the cost of some accuracy and allow for a high number of simulations. Figure 2 shows a typical flow pattern inside the main nozzle of an air jet loom.

Figure 1: Schematic of air jet loom (after L. Szabó and L. Szabó, International Journal of Engineering, 2012).

Figure 2: Typical flow pattern inside the main nozzle of an air jet loom. Note the shock pattern: a deviation in inlet pressure can significantly change this pattern and thus influence the forces on the yarn (source: N. Delaissé, 2019).

In recent years, several low-fidelity models have been developed in our research group. These models are deterministic: the geometry and inlet conditions are assumed to be exact. In reality however, quite some uncertainty is present in the system. Indeed, machines are manufactured up to a certain tolerance, inlet pressures might deviate from the set value and the yarns show a high degree of uncertainty in diameter and hairiness, to name a few. Including uncertainty in the optimization allows to estimate the importance of certain tolerances and the influence of deviations from a set point. For example, it may be possible to produce machines in a cheaper way if a certain nozzle part can be manufactured with less strict tolerances or the robustness can be increased by ensuring that the force on the yarn is in the right direction with a very high probability.