Probleemstelling:

In many textile machines, a yarn needs to be unwound from a cylindrical package to be processed. During this unwinding the yarn is subjected to several forces, including a tractional force on one end and resistance forces at the other end, but also aerodynamic and centrifugal forces due to the swirling motion of the yarn through the air and contact forces due to contact with rigid surfaces. The interplay between the forces is important to predict the behaviour of the unwinding, but it is not fully understood.

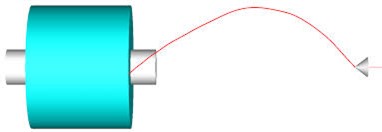

Figure 1: Unwinding of a yarn from a cylindrical package, creating so-called balloon formation.