Doelstelling:

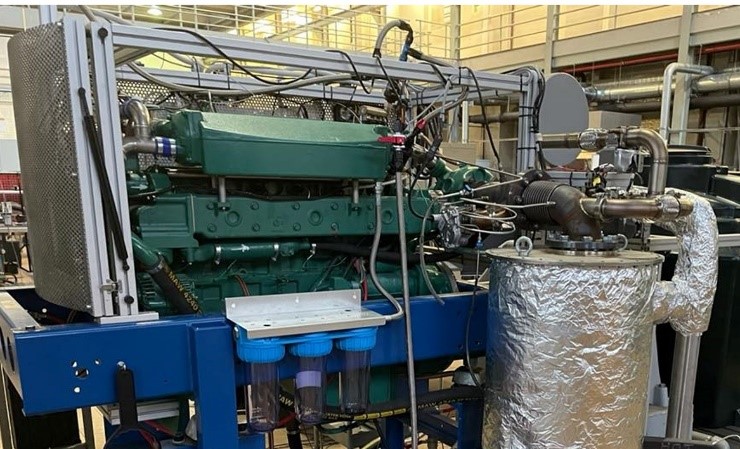

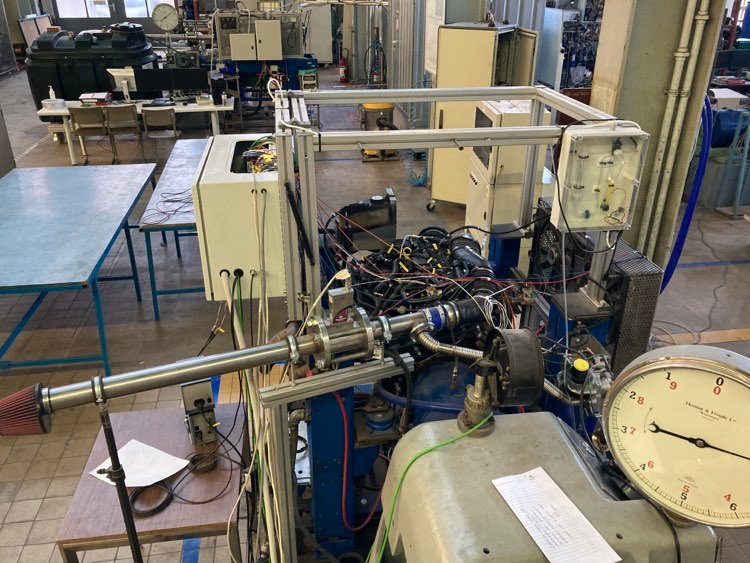

Within this experimental thesis two engines are available for exploring the knock-resistive properties of methanol. The first engine is a Volvo T3 gasoline car engine equipped with direct methanol injection and various variable settings such as variable valve timing and EGR. The second engine is a marine diesel Volvo Penta D7C engine that is currently running in diesel and dual-fuel (methanol-diesel) mode, and is equipped with a variable intake air temperature system, EGR and a waste gate.

The aim is to get a combined view on both engines on knock. Currently no knock is observed on the T3 given its low CR (10:1) and the high knock resistance of methanol, but increasing the intake air temperature by means of bypassing the intercooler could invoke knock. In this way, the hypothesis is to create a knock reference load point on the T3.

On the Penta the CR is 19:1. Therefore it is expected that knocking regions will be more easily encountered. However, before being able to investigate these knocking areas, the Penta should be commissioned on fully methanol SI operation. This is a first milestone to reach. In a next step the knocking regions can be exploited with the aim to search for the highest efficiency and power density.