Probleemstelling:

ArcelorMittal Gent is a steel production company which is situated in the port of Gent. It produces flat steel products, used amongst others in the automotive industry. Continuous casting is the part of the production process where liquid steel is cast into a continuous strand, which is cut into separate slabs. In other parts of the factory, these slabs are further processed to coils.

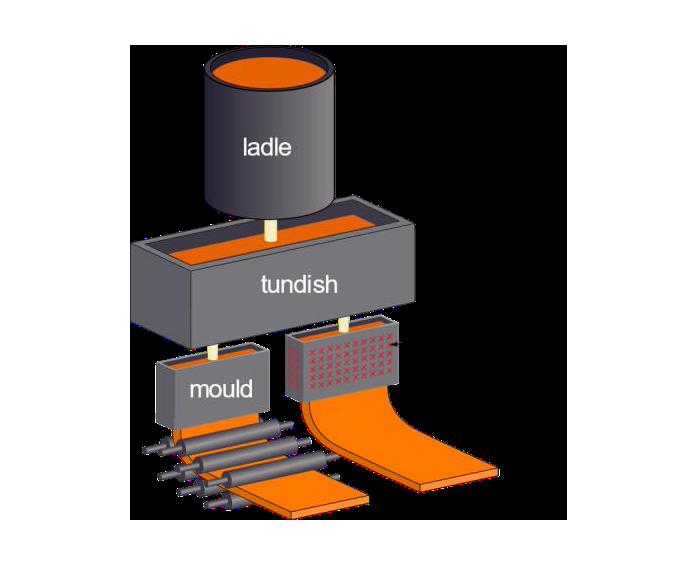

From ladle metallurgy, the liquid steel is transported to the continuous caster using a ladle. In the continuous caster, the liquid steel is then divided over two casting moulds using the tundish. The temperature of the liquid steel entering the mould should be within a tight margin: too cold means that it starts solidifying to early; too hot means a reduced casting speed (= quality issues and production loss) and a high energy cost at ladle metallurgy. Currently, a simple regression model is used to predict the temperature at the tundish during casting, starting from the temperature at the ladle metallurgy (= last place where they can adjust the temperature). This prediction model is then used to find the optimal temperature at ladle metallurgy based on the available planning (waiting time, cast duration, …).

The goal of this thesis is to develop a lu mped thermal model which can predict the temperature of the liquid steel in the tundish during casting. The model should take thermal losses and the thermal history of the tundish into account. This model is then verified with experimental data and compared with the current regression model.

mped thermal model which can predict the temperature of the liquid steel in the tundish during casting. The model should take thermal losses and the thermal history of the tundish into account. This model is then verified with experimental data and compared with the current regression model.